Maximize EV Battery Life with Advanced BMS & PCBs

An electric vehicle battery management system (BMS) is essential to keeping an EV running safely...

Matric has won awards for maintaining on-time delivery. The award qualifications include:

If you would like more information about how a full-service contract manufacturer can augment the abilities of your company and your equipment in the medical industry, fill out the form, let us know how we can help, and we will send you more information on what Matric can do for you.

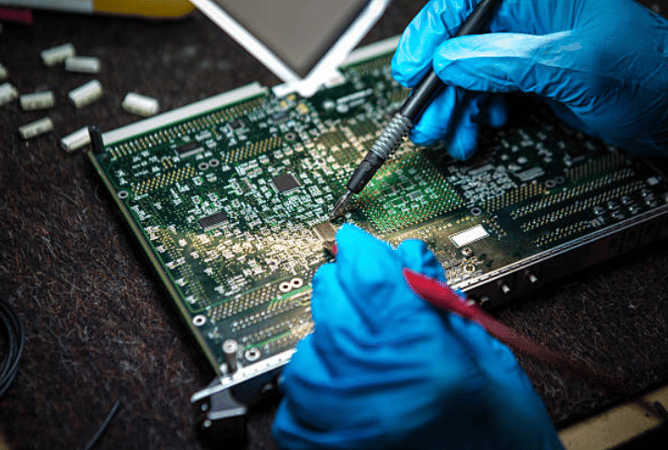

Medical devices and equipment are Class 3 electronics, which means you’re designing to a strict standard. Sometimes medical customers have special requirements and internal expectations that go beyond even Class 3.

The PCB manufacturer you work with needs to be able to meet all the requirements of Class 3 and any other requirements you may have. Some PCB companies specialize in Class 3 products, while others absolutely don’t. Do some investigating before you choose an ECM (electronics contract manufacturer).

If your medical device project will include PCB design and assembly, take these factors into consideration:

Because of strict industry requirements, companies responsible for selling finished medical devices score some important benefits when using a ISO 13485 certified manufacturer, including:

The first question when an OEM courts an electronics or other medical device component manufacturer should be: “Are you ISO 13485 certified?” The answer carries a lot of weight.

An electric vehicle battery management system (BMS) is essential to keeping an EV running safely...