Class 1, 2, & 3 Electronics: IPC Class Definitions

In electronics manufacturing, printed circuit boards are categorized based on the IPC Class...

Matric has won awards for maintaining on-time delivery. The award qualifications include:

If you would like more information about how a full-service military electronics manufacturer can augment the abilities of your company and your equipment in the military & defense industry, fill out the form, let us know how we can help, and we will send you more information on what Matric can do for you.

While its common for military & defense electronics to get lumped together with aerospace, there are significant differences between the two.

Nadcap certification may look enticing to a military/defense OEM, however there are few other standards that are just as important.

The United States Military Standards, MIL-STD for short, covers not just the end characteristics of a product, but also the process, materials, and security that need to be followed.

These defense standards ensure the logistical usefulness of every military product, and that each component performs properly every time.

As PCB designers continually innovate and evolve, so do defense standards. Particularly applicable to PCB component designs and manufacturing are:

In general, the best military-grade PCBs conform to specific parameters regarding dielectric thickness, annular rings, and drill-to-copper clearance.

The International Traffic in Arms Regulations, ITAR for short, regulates all sensitive information surrounding the production of military equipment.

The number of materials and processes regulated by ITAR is substantial but can be found here.

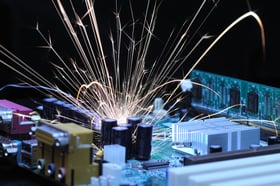

PCB failure can (and usually is) catastrophic, no matter the situation. When it comes to military and defense applications though, it could mean life or death.

Ensure your electronics contractor provides rigorous testing on all components with real-world applications.

In electronics manufacturing, printed circuit boards are categorized based on the IPC Class...